CNC Lathe

CNC HAAS ST-30 Y Lathe: unmatched metal fabrication

HISTORY OF LATHE MACHINES

Lathe machines date back to ancient Egypt. The machines played a huge role in the industrial revolution. The lathe is credited for being the machine that invented other machine tools.

The first lathes were used for woodworking. Today, lathes are used in almost all manufacturing process like; metal spinning, metal working, parts reclamation, thermal spraying, glass working, pottery, and many other applications.

Lathes such as the Haas ST-30 Y are crucial in metal working today because they combine technology and metal working perfectly. In fact, manufacturing of metals is unthinkable today without the CNC lathe machine.

The capabilities of the machines in metal working are limitless. They are used to produce plane surfaces, screw threads, solids of revolution as well as incredibly complex three-dimensional metal parts.

HOW CNC LATHE MACHINES WORK

CNC lathes are a fundamental part of the metal manufacturing technology/processes today. The machines are used to remove metal from a work piece to make an object with a desired shape and size.

They work by combining different material working processes together to make machining more effective. The work piece is usually rotated at variable or constant speeds while a tool or tools are introduced during the rotation to cut, shape or alter the work piece in the desired way.

CNC lathes cut, drill, groove, and ream to make desired final metal products. The machines also deform metals to create objects with symmetry. The latest CNC lathe machines can be programmed to meet many specifications and produce desired parts.

The Haas ST-30 Y, for instance, comes with a computer interface that allows the operator to manage the fabrication process via a visual simulation highlighting the functions of the machine during production.

Three videos from our shop showing how the CNC Lathe operates

WHAT MAKES UP A CNC LATHE MACHINE?

There are different kinds of CNC lathe machines today most of which are designed differently based on factors like the model, manufacturer, capabilities, etc. However, the machines have significant similarities.

For instance, CNC lathe machines have a turret; the part that holds tool holders and links them accordingly. CNC lathes also have a spindle which holds the work piece together. Other notable parts are the slides which give the turret motion in multiple axes simultaneously.

Lathes also have a bed, chuck, tool post, head stock, tail stock, lead screw, gear chain, carriage, split nut, cross slide, apron, guide ways and many other parts. These parts work together to offer the desired motion of a work piece or tool for it to be machined accordingly.

CNC lathes are completely enclosed for health/safety reasons.

In regard to design and use, different lathe manufacturers use different user interfaces. However, the computer systems are based on similar principles. The machines are generally easy to program.

MAIN BENEFITS OF CNC LATHE MACHINES

CNC Lathe machines have replaced conventional lathes due to their technological advancements which offer various benefits.

1. Speed: CNC lathe machines fabricate metal parts very fast. The latest CNC Lathe machines such as Haas ST-30 Y has unmatched speed capabilities (Spindle speeds of up to 4000 rpm and live tooling speeds of up to 6000 rpm).

The machines are also easy to set up and use which adds to the speed at which parts are fabricated. Furthermore, there is no need for manual labor in the production process which eliminates human-related delays. Fabrication is also faster than ordering new parts in most cases.

2. Top-notch accuracy and customization capabilities: The latest CNC lathe machines have tremendous repeatability capacity. The machines are designed to use the latest versions of carbide tooling/processes.

The machines’ tool paths are programmable using Master Cam Technology processes allowing unmatched customization capabilities and accuracy. Codes can be uploaded to the machine to produce parts with desired specifications automatically.

3. Cheaper than buying new parts: Fabricating metal parts is always cheaper than buying new parts. This is usually the case for most, if not all, applications involving metal equipment/parts.

At Basic Machining, we fabricate a wide variety of parts with our Haas ST-30 Y.

GETTING CNC LATHE SERVICES FROM BASIC MACHINING

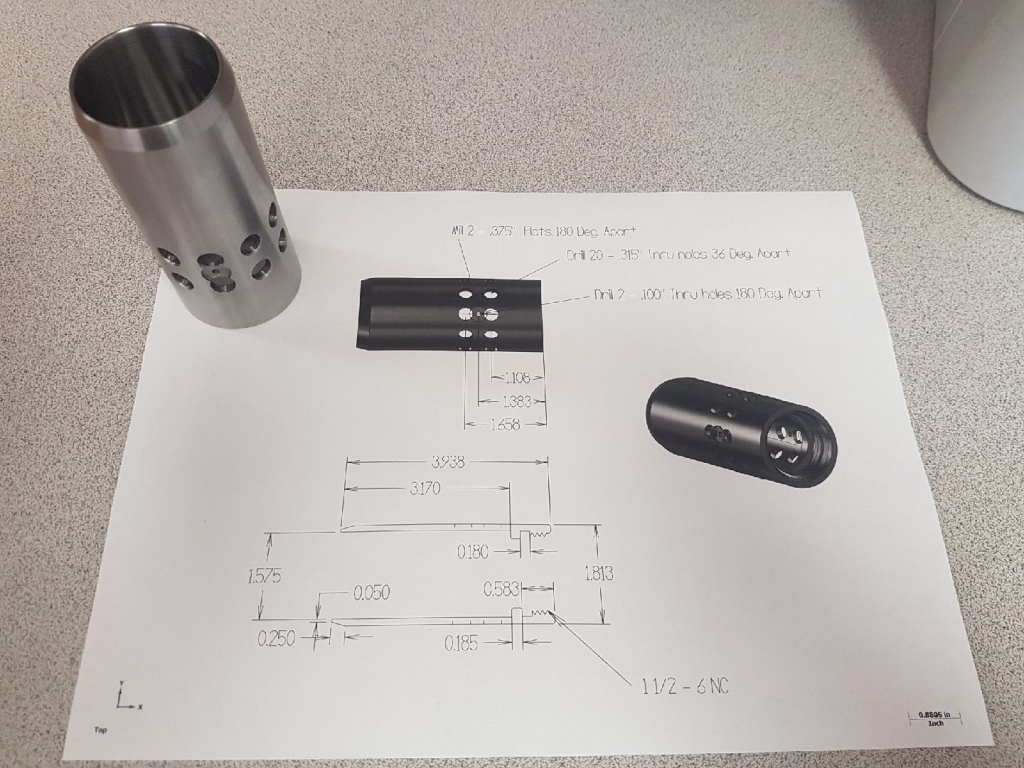

Do you want a metal part fabricated? Basic Machining can create any part from raw materials based on a drawing of the part, or from the old part. Here’s what you should do to get our CNC lathe services;

Step 1: Find the part that you want to be fabricated. It could be any part of a machine in a mine, mill, name it! We can fabricate failed or damaged parts in various production lines, heavy machinery, and equipment, etc.

Step 2: After identifying the part that needs fabricating, provide us with the drawings of the part. You can find part drawings in equipment files that come with purchased equipment. This information is important because it will help us know the exact type of material we should use, the specifications, design, etc.

Step 3: Send the drawings to us via email alongside other details, if any. If you can’t find the drawings, you can send us a picture or the old/damaged part.

Step 4: When we receive the drawings, pictures or parts we need to fabricate, our experienced CNC Lathe machinists will proceed and create Master Cam drawings that allow us to manufacture the part from scratch.

We have all the metal raw materials needed for fabricating most metal parts you want. It could be a plant machine part, engine part, metal equipment, etc. We have made countless metal parts from a piece of steel among other metals.

Our new CNC Lathe (Haas ST-30 Y) has amazing capabilities.

Interested in our services?We’re here to help!

© 2024

All Rights Reserved | Basic Machining Ltd.